Our quality target is: rolled throughput yield over 95%, delivered product yield of 100 percent, customer satisfaction percentage over 90%.

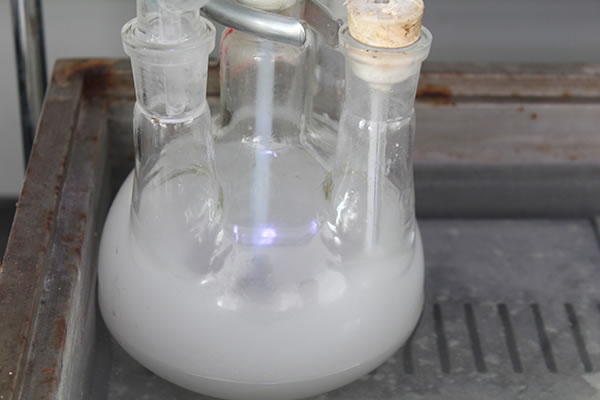

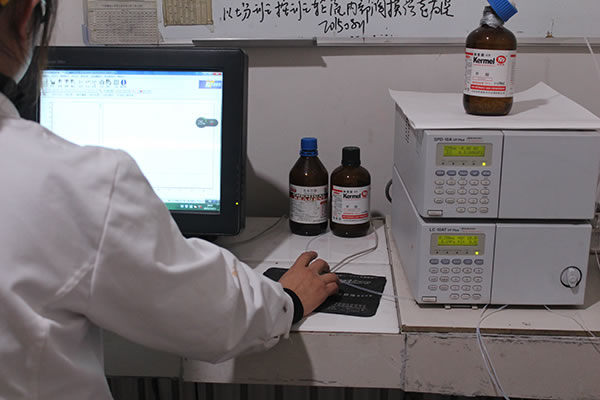

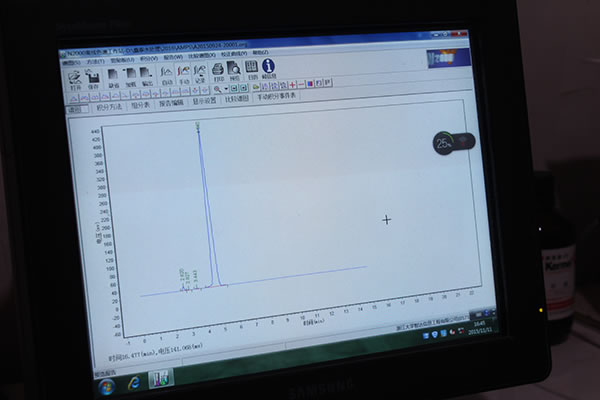

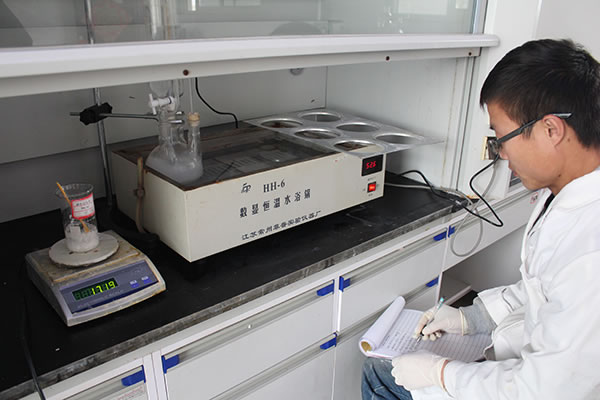

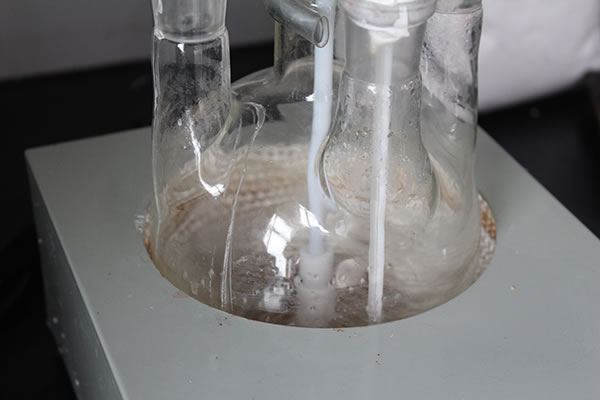

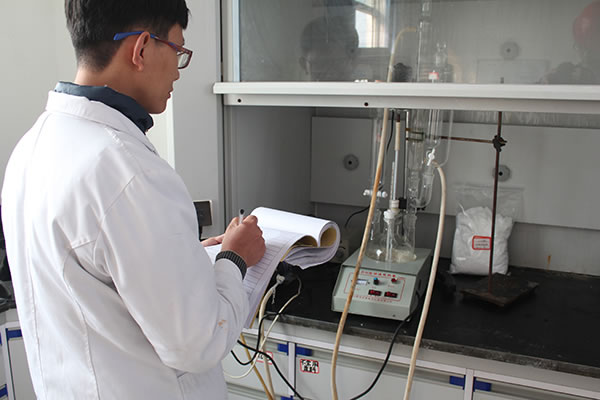

We have set strict quality standard on the procurement of raw materials. We compare several factories before purchasing each batch of raw materials and have a test cabinet that does sample examination. We reject uncompromisingly the unqualified materials. For each batch of products, production technicians, laboratory technicians and test cabinet technicians will make a detailed proportion scheme. Only after the success of the experiment, will we organize the production. During the production, the operators operate strictly according to the requirements and record the data in detail every 30 minutes. The test cabinet takes samples of products at a fixed time and location for detection and analysis according to the technological requirements. Once any abnormity is found, they notify immediately the related personnel to do the adjustments. All the records will be kept for future reference. Each batch of products realizes the traceability of production technology data and the quality detection data. As to the product charging, we measure every bucket and every bag. The finished product administrator does the sampling inspection before the products entering the warehouse. Every bucket and every bag of product has a clean appearance and clear logo to meet the national standard. For the transport, we sign transport protocols with the qualified logistics companies and do detailed transport plan for every batch of product. The field supervision of loading ensures the safety of transport.